We provide great, on time services to our valuable customers.

Stock and Custom High Density Polyethylene (HDPE)

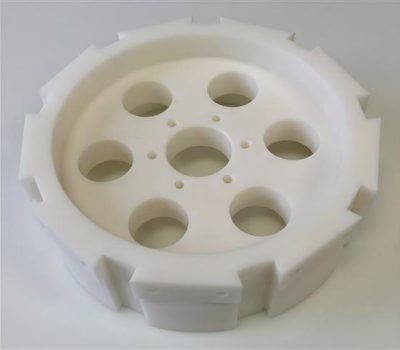

Custom Parts Manufacturer

We have the capabilities to fulfill your project requirements FAST and SAVE you money

CUSTOM POLYETHYLENE (HDPE, MDPE & LDPE) OEM DESIGNED PARTS MANUFACTURER

WSIL PLASTICS DIVSION stocks & design high-quality custom plastic parts using polyethylene. A leading custom extruder, WSIL PLASTICS offers an inventory of standard compounds of polyethylene, including HDPE, MDPE, and LDPE.

WHAT IS POLYETHYLENE?

Polyethylene is one of the most common plastics in use today. A thermoplastic polymer, polyethylene is available in different polymers grouped by the molecular weight, or density.

- HDPE – High density polyethylene is defined by a density greater than or equal to 0.941 g/m3. It is manufactured from petroleum and has a low degree of chain branching, resulting in strong intermolecular forces. HDPE has a high strength-to-density ratio, is corrosion and chemical resistant, and weatherproof.

- MDPE – Medium density polyethylene is defined by a density range of 0.926 – 0.940 g/m3. MDPE is produced by chromium/silica catalysts. MDPE exhibits good shock and drop resistance properties, with better stress.

- LDPE – Low density polyethylene is defined by a density range of 0.910 – 0940 g/m3. It is comprised of long and short chain branching, which results in weaker intermolecular forces than MDPE. It manufactured by free radical polymerization from the monomer ethylene. LDPE is more flexible than MDPE, strong, weatherproof, and chemical resistant.

Overall, polyethylene is a low cost, easy-to-process material. Some grades of polyethylene are recyclable.

Polyethylene is used for applications in the construction, plumbing, marine, furniture, and automotive industries. Some of the custom polyethylene parts we manufacture at WSIL PLASTICS are:

- Seals

- Tubing

- Custom Design Bends

- Weather-strips

- Guards

- Cord

- Bindings

- Step treads

- Chock Blocks

POLYETHYLENE ADVANTAGES

- Low cost

- Impact resistant from -40° to 194° F

- Moisture resistant

- Food grades available

At WSIL PLASTICS, we utilize sustainable, environmentally-responsible manufacturing practices, to minimize waste and maximize energy efficiency in our manufacturing. We can assist you in selecting environmentally friendly alternatives or compounds for your project.

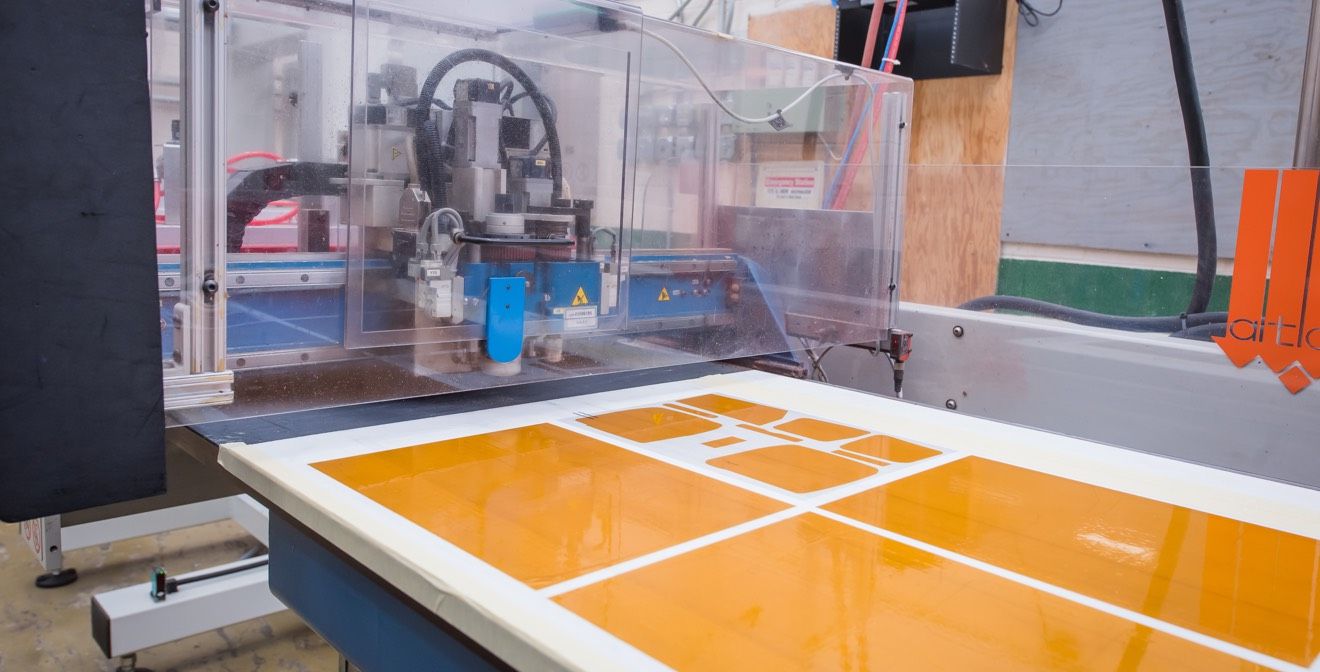

WSIL PLASTICS operates production facilities that provide the capacity to extrude simple and complex shapes to the tightest tolerances and exacting requirements. Our turnkey services include complete finishing services, including close tolerance cutting, precision drilling, notching, punching, trimming, welding, stamping, and custom packaging. WSIL PLASTICS is ISO 9001:2015 certified.

At WSIL PLASTICS, we are committed to manufacturing a high-quality part that meets your expectations, is delivered on time and on budget – all supported by superior customer service. We understand that the components and parts we deliver you are critical to the performance of your finished products and that the quality of our products impacts the quality of your products – and that it’s your reputation on the line. It’s that commitment that keeps our customers coming back.

WSIL PLASTICS, specializes in more complex assembly by bending, forming, notching, punching, gluing, riveting and other techniques. We have the ability to produce virtually any component that lends itself to flexible or rigid HDPE. If you have special requirements we invite you to discuss them with our technical staff, please call or email today.

Custom OEM Components

From gaskets, o-rings and seals to molded & extruded polymers, we can work with you to create the perfect OEM components. We work directly with large corporations and Tier 1 suppliers to create highly specialized solutions to complex issues. Let our experienced staff help you stay on target and under budget.

Plastic Bending & Plastic Forming Services

To turn raw plastic materials into the custom parts and components you need, WSIL PLASTICS provides plastic bending and plastic forming services. Our bending and forming capabilities enable us to deliver plastic parts that meet your unique specifications.

Plastic Bending & Forming Capabilities

Our in-house bending/forming oven helps make plastic materials more pliable and easier to work with, thus ensuring higher precision bends and radiuses and better overall quality of bent and formed parts.

In-House Mold Making

With an in-house machine shop, we can create custom male-female molds for plastic forming. These molds are custom-made to match our customers’ exact designs. Simply provide us with your part design files, and we’ll produce the molds needed to form your parts. This helps us deliver high quality formed plastic parts with perfect repeatability from the first piece to the last.

Design for Manufacturability

To make your plastic parts and components easier—and therefore less expensive—to produce, WSIL PLASTICS offers “design for manufacturability” service. Working from your original designs, we can suggest modifications and alterations that will reduce the complexity of your formed, bent, or fabricated parts without sacrificing performance. Ultimately, this gives you better quality parts, with the fit and functionality you need, at lower costs and often with faster turnaround times.

Contact Us for Plastic Forming, Bending & More

Send us Your Requirement

WELOK STEEL INDUSTRIES LLP’s Steels stocks a wide range of materials and grades. Below are a list of all standard sheets and plates materials and grades we stock