We provide great, on time services to our valuable customers.

Quality is the basic business principle at WELOK STEEL INDUSTRIES LLP

We strongly believe in the principle that “Quality is profit, Quality is the life of the enterprise.” For consistently delivering quality end products, we have with us, well developed:

Process

The system controls the quality of all incoming materials as per the raw material test certificate of the material. Randomly checking in each size for chemical and physical properties at Government approved laboratory.

During forming pressing forging and heat treatment process control system outlines in process checks and controls to be followed during heat treatment and testing.

Suitable fixtures and templates are used to maintain dimensional accuracy necessary gauges and calipers are calibrated periodically to maintain their accuracy.

Fitting are supplied with test certificate as per approved QAP. Test certificates incorporate chemical composition, mechanical properties hardness detail of heat treatment Ultrasonic test Radiography test and stamping details.

We are committed to develop, implement and maintain an effective Quality Management System in compliance.

| Product | Process of Manufacturing | Quality Tests | |

| Mandatory Testing | Additional Testing (As per Client’s Requirements) | ||

| Seamless Butt Weld (BW) Fittings | a) Conventional Sand Filling b) Mandrel c) Cold Hydro Forming | Chemical | Impact Test : V – Notch& Charpy |

| Tensile | Hydro /Leak Proof Test – Pipes Only | ||

| Hardness | IGC – (SS Materials Only) | ||

| Ultrasonic Testing (UT) | Macro Test | ||

| Dye Penetrant Test (DP) | Ferrite Test | ||

| Magnetic Particle Inspection (MPI) | Grain Size Test (SS Materials only) | ||

| PMI (For AS & SS Materials only) | |||

| Moly Test (SS Materials only) | |||

| Welded Butt Weld (BW) Fittings | Welding | Chemical | Impact Test : V – Notch & Charpy |

| Tensile | IGC – (SS Materials only) | ||

| Hardness | Micro Test | ||

| Radiography Testing (RT) | Macro Test | ||

| Ultrasonic Testing (UT) | Ferrite Test | ||

| Dye Penetrant Test (DP ) | Grain Size Test (SS Materials only) | ||

| Magnetic Particle Inspection (MPI) | Bend Test | ||

| PMI (For AS & SS Materials only) | Hydro Test | ||

| Moly Test (SS Materials only) | |||

| Socket Weld & Screwed Fittings | Forging | Chemical | Impact Test : V – Notch & Charpy |

| Hardness | IGC – (SS Materials only) | ||

| Ultrasonic Testing (UT) | Macro Test | ||

| Magnetic Particle Inspection (MPI) | Ferrite Test | ||

| PMI (For AS & SS Materials only) | Grain Size Test (SS Materials only) | ||

| Moly Test (SS Materials only) | |||

| Flanges | Forging | Chemical | Impact Test : V – Notch & Charpy |

| Hardness | IGC – (SS Materials only) | ||

| Ultrasonic Testing (UT) | Macro Test | ||

| Magnetic Particle Inspection (MPI) | Ferrite Test | ||

| PMI (For AS & SS Materials only) | |||

| Moly Test (SS Materials only) | |||

| Flanges | From Plates | Chemical | Impact Test : V – Notch & Charpy |

| Hardness | IGC – (SS Materials only) | ||

| Ultrasonic Testing (UT) | Macro Test | ||

| Magnetic Particle Inspection (MPI) | Ferrite Test | ||

| PMI (For AS & SS Materials only) | |||

| Moly Test (SS Materials only) | |||

| Bends | Induction Bending | Chemical | As per Client’s Requirement |

| Hardness | |||

| For Welded – Radiography Testing (RT) | |||

| For Welded – Dye Penetrant Testing (DP) | |||

| For Seamless – Magnetic Particle Inspection (MPI) | |||

| PMI (For AS & SS Materials only) | |||

| Moly Test (SS Materials only) | |||

COMMITMENT TO QUALITY

Quality is Always First Priority

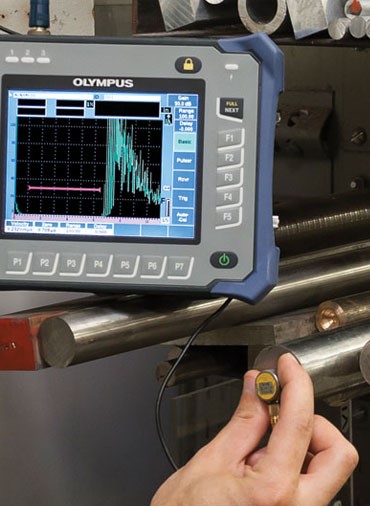

At WELOK STEEL INDUSTRIES LLP, our employees adhere to and contribute to the efficiency of our quality system in every aspect of our business. Our quality control team combines technical expertise, knowledge of industry standards and the latest inspection tools and machines to meet all requirements. Particular attention is paid to high quality, tolerance and traceability.

Our Quality Key Principles

Understand our markets, customer needs, and continuously improve our service to facilitate growth. Continuously monitor customer satisfaction and consistently provide products, processes, and services that meet and exceed customer expectations. Focus on continuous improvement on our quality management system to ensure its continuing suitability to enable us to stay ahead of the competition. Our employees adhere to and contribute to the efficiency of our quality system in every aspect of our business. Our commitment guarantees to provide our clients with uncompromising quality and service. This is achieved through a team approach where all the members are aware of the company objectives and work within their own discipline to make an effective contribution. To verify that the supply made to our clients exact specifications, our quality control team combines technical expertise, knowledge of industrial standards and the latest inspection tools and machines to meet all requirements. Particular attention is paid to high quality, tolerance and traceability.

Our in-house test facility houses:-

TESTINGS (DESTRUCTIVE, NON DESTRUCTIVE):

- Positive Material Identification – PMI Testing

- Chemical Analysis – Spectro Analysis

- Mechanical Testing Such as Tensile, Elongation, Reduction of Area

- Micro Test

- Macro Test

- Hardness Test

- Pitting Resistance Test

- Intergranular Corrosion (IGC) Test

- Flaring Test

- Flattening Test

- Hydrostatic Test

- Hydrogen-Induced Cracking (HIC) Test, NACE TM0284

- Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177

- Radiography Test

- Dye Penetrant Test (DP Test)

- Ultra Sonic Test (UT)

- Eddy Current Testing

- Impact Test

- Bend Test

PACKING:

- We understand the importance of packaging specially in case of international shipments as the consignment has to go through a number of channels to reach the final destination, thus we take proper care of packing.

- We pack our goods in a various ways depending on the products. The different ways in which our products are packed are:

- Shrink-wrapped

- Wooden Boxes

- Wooden Pallets

- Wooden Crates

- Carton boxes

MARKING:

- All our products will have complete marking details which are co-related to the test certificates we supply.

- In case of orders for cut piece of Pipes, Sheets or Round Bars, the marking is transferred from the product from which it is cut. In such cases we provide Letter confirming the marking transfer and picture of the product from which it is cut.

DELIVERY TIME:

- If the items are available in stock, we take 2 days from the date of receipt of advance payment to clear the shipment and send it to port.

- And in-case the items are not availabe in stock, the time taken for manufacturing depends on the size, quantity and grade.

- However we can claim the fact that we can compete with anyone in India on Delivery time and most of the time our production time is the least.

- We have tied up with strong logistic partners in India which can undertake any type of shipping activites and make sure that there is no delay in shipment.

INSPECTION:

- We welcome stage wise inspection, final stage inspection from any of your representative or third party inspection agencies.

- We regularly have inspections ongoing at our premises from internationally acclaimed Inspection Agencies such as TUV, Llyods, BVIS, SGS, DNV etc.

Send us Your Requirement

WELOK STEEL INDUSTRIES LLP’s Steels stocks a wide range of materials and grades. Below are a list of all standard sheets and plates materials and grades we stock